Tower Gamma Scanning Services

Nuclear Scanning Services understands the importance of tower gamma scanning in identifying online hydraulic conditions in your process equipment. Our tower gamma scanning services are essential in gas plants, chemical plants, pharmaceuticals, refineries, or any process that involves density measurement. Our team is committed to delivering optimal results to ensure maximum efficiency, safety, and productivity in your processes.

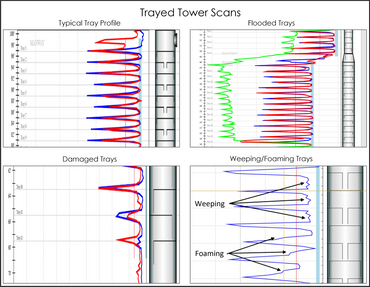

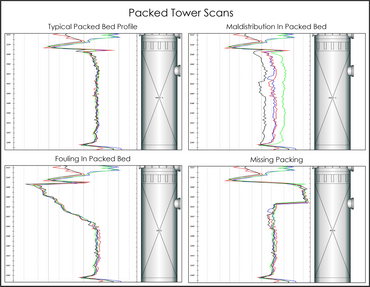

Tower scans (column scans) utilize non-destructive gamma scanning technology. Primarily, this technique is used to locate mechanical damage and depict process flow characteristics inside distillation towers while they remain in service.

Tower scans are safe, proven, remain completely external to the process, do not interfere with plant operations, require no plant utilities, and are also set up and performed quickly. The efficiency of our data collection process allows several re-scans at varying operating conditions in minimal time.

In addition to locating and identifying problem areas, tower scans enable your process and technical personnel to more fully understand their process and the nature of instability or poor performance.

As well as identifying problem areas that allow personnel to plan for a scheduled shutdown, gamma scanning towers can also eliminate a potential shutdown by showing that tower inefficiencies are not due to internal problems. Gamma scans are a safe and efficient way to indicate where process personnel should concentrate efforts to solve operating problems.

By analyzing this density profile, our engineers can readily determine:

- Location of damaged or missing trays.

- Aerated liquid loadings on trays

- Location and extent of flooding

- Location and severity of entrainment

- Location and density characteristics and extent of foam (when present)

- Downcomer liquid levels, base liquid levels

- Integrity of demister pads and distributors

- Integrity of packed beds and catalyst beds

- Liquid/vapor distribution within packing

- Draw pan, Chimney tray, and distributor integrity and liquid retention

- Scale, coke, or hydrates buildup/formation

COLUMN SCAN IMAGE GALLERY (CLICK TO VIEW INDIVIDUAL IMAGES)

Copyright © 2026 Nuclear Scanning Services - All Rights Reserved.

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.